If you are looking for MS-53 IGNOU Solved Assignment solution for the subject Production/Operations Management, you have come to the right place. MS-53 solution on this page applies to 2023 session students studying in PGDOM, MBA, MPB courses of IGNOU.

MS-53 Solved Assignment Solution by Gyaniversity

Assignment Code: MS-53/TMA/JAN/2023

Course Code: MS-53

Assignment Name: Production/Operations Management

Year: 2022-2023

Verification Status: Verified by Professor

Attempt all the questions and submit this assignment to the coordinator of your study centre. Last date of submission for January 2023 session is 30th April 2023 and for July 2023 session is 31st October 2023.

Q1) What do you mean by my input-transform-output process in production/operations management? Develop Input-Process-Output block diagram for the following.

a. Bank

b. Hospital

c. Restaurant

d. University

Ans) In production/operations management, the input-transform-output process refers to the series of activities that transform input resources into output products or services. This process involves several steps, including planning, scheduling, staffing, controlling, and evaluating. In this context, input resources refer to the raw materials, equipment, and human resources that are required to carry out the production process, while output products or services refer to the finished goods or services that are delivered to customers.

To better understand the input-transform-output process in different industries, let's develop input-process-output block diagrams for a bank, hospital, restaurant, and university.

Bank

Input Resources: Money, customer information, staff, banking equipment.

Process: customer transactions, account management, loan processing, fraud detection.

Output: satisfied customers, financial products, revenue, financial reports.

Hospital

Input Resources: Medical equipment, staff, medication, patient data, medical supplies

Process: patient diagnosis, treatment, surgery, rehabilitation, emergency care

Output: healthy patients, medical reports, satisfied patients, revenue

Restaurant

Input Resources: Food, staff, kitchen equipment, dining space

Process: Food preparation, cooking, serving, billing

Output: satisfied customers, revenue, food waste, customer feedback

University

Input Resources: Faculty, staff, students, classroom space, educational materials.

Process: Teaching, research, administration, student support services.

Output: Educated students, research publications, satisfied faculty and staff, revenue from tuition and grants.

In each of these industries, the input resources are transformed through a series of processes into output products or services. By analysing and improving each step in the input-transform-output process, organizations can improve their efficiency, quality, and customer satisfaction.

Q2) What is capacity planning? Discuss the aspects and determinants of capacity planning with suitable examples.

Ans) Capacity planning is the process of determining the production capacity an organization needs to meet its future demand requirements. It involves identifying the optimal level of resources and infrastructure required to produce goods or services and ensuring that these resources are available when needed. The goal of capacity planning is to balance the supply and demand for a product or service, and to ensure that the organization can meet its commitments to customers in a timely and cost-effective manner.

Aspects of Capacity Planning

Strategic Capacity Planning: This involves long-term planning, typically over a period of several years, and is aimed at determining the overall capacity requirements of the organization. This involves analysing future demand projections and ensuring that the organization has the resources and infrastructure to meet this demand.

Tactical Capacity Planning: This involves medium-term planning, typically over a period of a few months to a year. It focuses on balancing the supply and demand in the short to medium term, and may involve adjustments to staffing levels, production schedules, and other operational factors.

Operational Capacity Planning: This involves short-term planning, typically over a period of a few weeks to a month. It involves making real-time adjustments to production schedules and staffing levels to meet changing demand requirements.

Determinants of Capacity Planning

Demand: The level of demand for a product or service is the primary determinant of capacity planning. Organizations need to ensure that they have sufficient capacity to meet expected demand, while avoiding overproduction, which can result in excess inventory and waste.

Production Technology: The production technology used by an organization can also influence capacity planning. Different production technologies have different levels of efficiency and require different levels of resources, which can affect the amount of capacity required.

Resource Availability: The availability of resources such as labour, raw materials, and equipment can also impact capacity planning. Organizations need to ensure that they have sufficient resources to meet their production needs.

Cost: The cost of adding capacity is an important consideration in capacity planning. Organizations need to balance the costs of adding capacity against the potential benefits of increased production.

Example

Consider the case of a manufacturing company that produces automobile parts. The company needs to engage in capacity planning to ensure that it has sufficient capacity to meet expected demand for its products. The following are some of the determinants of capacity planning in this case:

Demand: The company needs to analyse future demand projections for automobile parts and ensure that it has sufficient capacity to meet this demand.

Production Technology: The company needs to consider the efficiency of its production technology and the level of resources required to produce its products. For example, if the company can produce parts more efficiently using new technology, it may need to invest in this technology to increase its capacity.

Resource Availability: The company needs to ensure that it has sufficient resources such as labour, raw materials, and equipment to meet its production needs. If resources are limited, the company may need to consider outsourcing or investing in additional resources.

Cost: The company needs to balance the costs of adding capacity against the potential benefits of increased production. For example, it may need to consider the costs of investing in new equipment or hiring additional staff against the potential benefits of increased production.

Capacity planning is a critical aspect of operations management that involves determining the optimal level of resources and infrastructure required to produce goods or services. By analysing demand projections and considering factors such as production technology, resource availability, and cost, organizations can ensure that they have sufficient capacity to meet their production needs while remaining cost-effective.

Q3) Discuss various qualitative methods of forecasting.

Ans) Qualitative methods of forecasting rely on expert opinion, judgment, and subjective assessment rather than statistical analysis. These methods are useful when there is no historical data available or when the future is uncertain. Here are some of the commonly used qualitative methods of forecasting:

Delphi Method: This method involves a panel of experts who are asked to provide their opinions and estimates about future events. The results are then aggregated and analysed to arrive at a consensus forecast.

Market Research: This method involves gathering information about consumer preferences, attitudes, and behaviours to forecast demand for a product or service. Surveys, focus groups, and customer interviews are common market research techniques.

Scenario Analysis: This method involves developing different scenarios or possible futures based on different assumptions and variables. This approach helps to identify potential risks and opportunities and provides a range of possible outcomes.

Expert Opinion: This method involves gathering opinions and insights from experts in a particular field. Experts may be asked to provide their opinions about future trends, technologies, or market conditions.

Historical Analogy: This method involves looking at past events or situations that are similar to the current situation and using them as a basis for forecasting. For example, a company may look at past sales trends during an economic recession to forecast sales during the current recession.

Brainstorming: This method involves generating ideas and insights through a group discussion. It can be useful in generating new ideas and identifying potential opportunities and threats.

Nominal Group Technique: This method is like brainstorming but involves a more structured approach. Participants are asked to provide their ideas and insights individually, which are then shared and discussed as a group to arrive at a consensus forecast.

Qualitative methods of forecasting can be useful when there is no historical data available or when the future is uncertain. However, they are often subjective and can be influenced by the biases and opinions of the experts involved. It is important to use multiple methods of forecasting and to compare the results to arrive at a more accurate forecast.

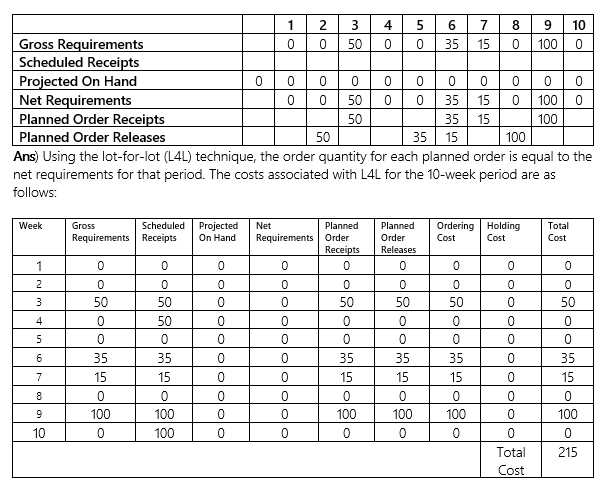

Q4) Hip Replacements, Inc. has a master production schedule for its newest model, as shown below, a setup cost of `50, a holding cost per week of `2, a beginning inventory of 0, and a lead time of 1 week. What are the costs of using lot-for-lot for this l0-week period?

The ordering cost is `50 per order, which is incurred each time a planned order is released. The holding cost is `2 per unit per week, which is incurred for each unit held in inventory.

The total ordering cost for the 10-week period is `350 (`50 x 7 planned order releases), and the total holding cost is `0 since there is no inventory held at the end of the period. Therefore, the total cost of using L4L for the 10-week period is `215 (`350 in ordering cost plus `0 in holding cost).

Using L4L can result in frequent ordering and setup costs, which can increase the total cost of production. However, it can also reduce the amount of inventory held in stock, which can reduce holding costs. Overall, the choice between different lot sizing techniques depends on the trade-off between ordering and holding costs, lead time, and the level of demand uncertainty.

Q5) What is Just-in-Time production? How does it differ from Manufacturing Resource Planning (MRP)? What is MRP-JIT system?

Ans) Just-in-Time production is a manufacturing philosophy that emphasizes producing the right quantity of products at the right time to meet customer demand. JIT production focuses on reducing waste, increasing efficiency, and improving quality. JIT production relies on close collaboration with suppliers and customers to achieve seamless production and delivery of goods.

Manufacturing Resource Planning (MRP) is a computerized inventory management system that helps businesses plan their production activities. MRP focuses on optimizing inventory levels and production schedules to meet customer demand. MRP uses a bill of materials (BOM) and inventory data to generate production schedules and material requirements.

The main difference between JIT and MRP is the approach to managing inventory. JIT production aims to minimize inventory levels by producing products as needed, while MRP aims to optimize inventory levels based on demand forecasts. JIT relies on close collaboration between suppliers and customers to deliver raw materials and finished products as needed. In contrast, MRP relies on a complex software system to plan production and manage inventory levels.

MRP-JIT system is a hybrid approach that combines the benefits of both JIT and MRP. The MRP-JIT system uses the forecasting and planning capabilities of MRP to determine the optimal inventory levels and production schedules. Once the plan is in place, the JIT approach is used to produce products in small batches as needed. This approach helps to minimize inventory levels while still maintaining the ability to meet customer demand.

The MRP-JIT system has several advantages over traditional MRP systems. First, the MRP-JIT system can reduce inventory levels and associated costs. By producing products in small batches, the MRP-JIT system minimizes the need for large inventories. Second, the MRP-JIT system improves the flexibility and responsiveness of the production system. By producing products in small batches, the MRP-JIT system can quickly respond to changes in customer demand. Finally, the MRP-JIT system promotes closer collaboration between suppliers and customers. By working closely together, suppliers and customers can better anticipate demand and adjust production schedules accordingly.

JIT production and MRP are two different approaches to managing production and inventory levels. While JIT emphasizes producing the right quantity of products at the right time, MRP focuses on optimizing inventory levels and production schedules. The MRP-JIT system is a hybrid approach that combines the forecasting and planning capabilities of MRP with the flexibility and responsiveness of JIT. By using the MRP-JIT system, businesses can reduce inventory levels, improve flexibility, and promote closer collaboration between suppliers and customers.